Antwort What is Shine 5S? Weitere Antworten – What is the 5S concept of shine

5S Meaning in English

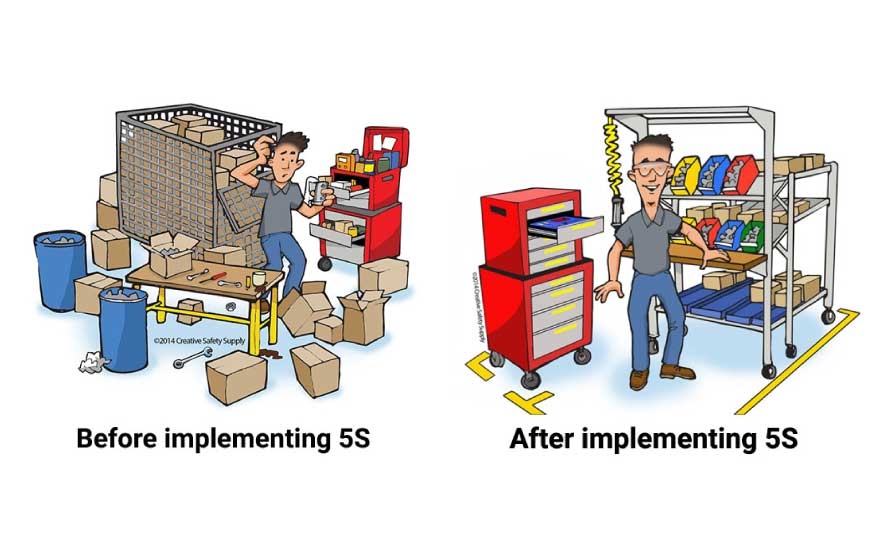

Sort (Seiri): Eliminate that which is not needed. Straighten (Seiton): Organize what remains after sorting. Shine (Seisou): Clean and inspect the work area. Standardize (Seiketsu): Write standards for 5S.Method and Implementation Approach. 5S is a cyclical methodology: sort, set in order, shine, standardize, sustain the cycle. This results in continuous improvement.5S was derived from the Japanese words seiri, seiton, seiso, seiketsu, and shitsuke. In English, they can be roughly translated as sort, set in order, clean, standardize, and sustain. The cornerstone of 5S is that untidy, cluttered work areas are not productive.

What are the aims of the S3 shine : Shine: Regularly clean and keep the workplace cleansed through general cleaning and daily cleaning of machinery, equipment, and working areas. The S3 aims to improve the working environment, reduce risks and accidents, and reduce the influence of dirt improving the capacity of equipment (due to the influence of dirt).

Why is shine important

Shine focuses on cleanliness, regular maintenance, and creating a safe working environment. Maintaining a clean and organized workplace is not only aesthetically pleasing but also crucial for ensuring safety and efficiency.

What is seiso or shine : Shine (seiso) – Regularly maintain and clean your workspace and equipment. Seiso or Shine requires regular cleaning of the workspace, prevention of any deterioration of equipment, and maintenance of a pleasant workplace. Any deviations or malfunctions in the workplace (things not being in place, broken machinery etc.)

The five S's represent the five steps, based on the original Japanese words of seiri, seiton, seiso, seiketsu, and shitsuke, but translated into English to sort, set, shine, standardize and sustain.

One of the best ways to measure and improve your 5S system is to conduct regular audits and inspections of your workplace. You can use checklists, scorecards, or visual tools to assess the level of compliance and improvement in each of the 5S steps: sort, set in order, shine, standardize, and sustain.

What is 6S

The six steps of the 6S method are: Seiri (sort), Seiton (set in order), Seiso (shine), Seiketsu (standardize), Shitsuke (sustain), and Safety (safety). Seiri (Sort) Unnecessary tools and materials are identified and sorted out. This makes the workplace more organized and creates more space for needed work materials.5s Lean is a systematic approach aimed at optimizing workplace operations by reducing waste, improving efficiency, and creating an organized environment. The methodology derives its name from its core principles: Sort, Set in Order, Shine, Standardize, and Sustain.In the United States, 3S is perhaps best popularized by Paul Akers. And yet he learned it from a Japanese company named Hoks. It's a simplified version of 5S. 5S stands for Sort, Straighten, Sweep, Standardize, and Sustain. 3S is just three of these: Sort, Sweep, and Standardize.

Shine (Seiso)

The third stage of the 6s lean system, also known as 'Shine', includes activities, such as cleaning the workplace, maintaining its pleasant appearance, and using preventive steps to keep workspaces tidy and clean.

Who is the father of 5S : Taiichi Ohno

The Japanese methodology 5S is depended on five various pillars: Seiri (Sort), Seiton (Set in order), Seiso (Shine), Seiketsu (Standardize) and Shitsuke (Sustain). In past, 5S was known as the Toyota Production System, which was developed by Taiichi Ohno and Eiji Toyoda with Japanese industrial engineers in 1950.

What is seiso in 5S : Seiso (Clean)

The third S, Seiso, means clean. It recommends not only keeping work areas clean, but also taking care of the maintenance of tools and machines. This is the first step towards self-maintenance, as cleaning is often an opportunity to detect premature wear and tear or anomalies.

What is a shine work area

Among the 5S steps, Shine (Seiso in Japanese) refers to the process of cleaning and inspecting work areas and equipment thoroughly. It's more than just tidying up—it's about ensuring that every nook and cranny is pristine, free of dust, dirt, or potential hazards.

The 5S methodology in Kaizen is based on the initial letters of five Japanese words: Seiri (Sort), Seiton (Straighten), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). This approach was originally developed to improve efficiency by organizing operations and workspaces.The name comes from the five steps Sort, Set, Shine, Standardise, and Sustain. The goal of 5S is to eliminate waste and improve efficiency by creating a well-organised and clean workplace.

Is 5S the same as Six Sigma : 5S focuses on eliminating waste and inefficiencies in the workplace. This methodology can be applied to every department and action that takes place. On the other hand, Six Sigma is a process improvement strategy that eliminates defects by implementing standard processes, identifying problem areas, and more.