Antwort How hard is it to learn CNC? Weitere Antworten – How long does it take to learn CNC

You should expect it to take over 3 years of hard work to master but it can take just a few hours of easy tutorials to create basic parts. Like most skills, CNC machining is a skill that is built upon through experience and trial and error.The good news is that you don't necessarily need to study engineering in a college or university in order to start learning CNC and evolve as a competent CNC professional. However, you definitely need to have some skills and qualities in order to succeed in the CNC field.CNC machinists work in a world where a micrometer, or a thousandth of an inch, can be the difference between perfection and waste. The high level of precision required, along with stringent quality control, constitutes one of the job's primary challenges.

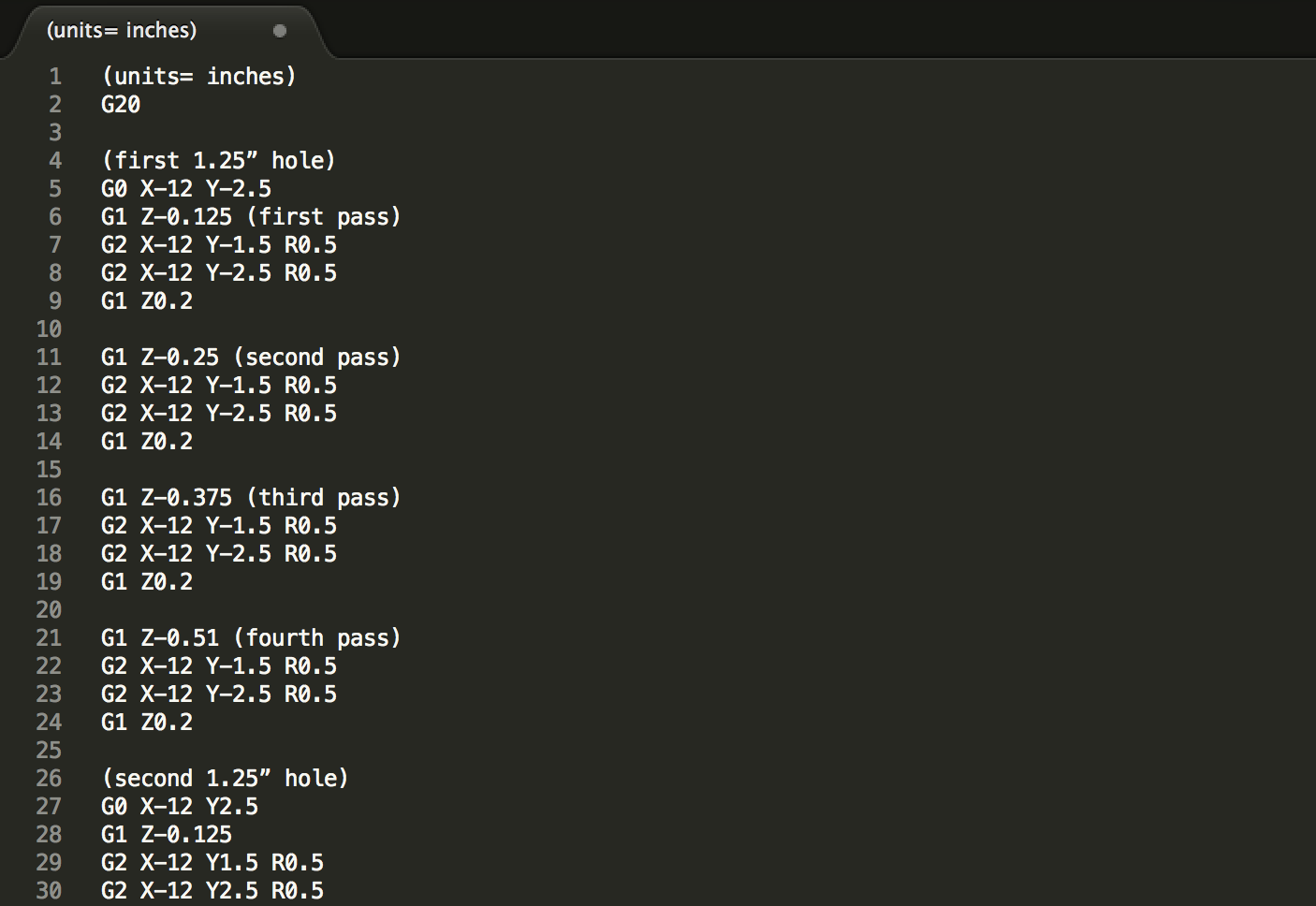

Is CNC coding hard : Programming a CNC machine is complex and difficult. Never tediously vet or check your G-code again. Autodesk Fusion makes it easy to produce parts faster the first time.

Does CNC require math

Machine shop math is an important consideration for CNC programmers and machinists.

Is CNC machining stressful : CNC machining can be physically demanding, mentally challenging, and stressful at times. It demands precision, attention to detail, and a commitment to continuous learning.

Spoiler alert, in Precision Machining, we all use a lot of math through algebra, geometry trig and statistics. Our machinists and quality technicians use and apply algebra, geometry, trig and statistics on the job everyday.

Myth #1: CNC machining is a dying trade

Fact: Far from it!

Is CNC a good career choice

Benefits of a CNC Machining Career

The surge in demand for precision, automation, and production efficiency contributes to the growth. Automation and advanced machining doesn't negate the need for skilled employees–in fact, adopting new technologies create the need for CNC experts to play new roles.Can you make money with CNC router projects Yes! There's a whole host of CNC-based businesses that make money online by creating and selling custom-made products with their CNC router.Very basic CNC programming is easy to learn, provided that you understand basic math and have a grasp of how machining works. This can usually be learned within a few days. Intermediate programming skills can be learned within a year and advanced CNC programming can take several years to learn.

Machine shop math is an important consideration for CNC programmers and machinists. One of the more common problems I have seen in my years in the machine shop is a general lack of readily available and handy information on machine shop math – specifically on feeds, speeds and related formulae.

Is there money in CNC work : Those with advanced skills can even charge upwards of $50 an hour. Whether you work for an employer or freelance, being a CNC machinist can be a good way to earn a handsome income.

Are CNC programmers happy : Unlike other manufacturing roles, which usually only handle one aspect of the entire process, CNC programming allows you to see your ideas turn into reality. This can improve work satisfaction and can provide you with the positive feeling of seeing a project from its planning phase to completion.

Can you make a living with a CNC machine

One profitable way to make money with CNC machines is by manufacturing precision parts and components for various industries. CNC metalworking machines can produce high-quality products with utmost precision from small intricate pieces to large-scale components.

CNC machines support profitability because they allow you to automate many time-consuming manual tasks in applications such as woodworking or metalworking. This allows you to increase your output without taking on additional labor costs.How Much Do Cnc Machinist Jobs Pay per Year $41,000 is the 25th percentile. Salaries below this are outliers. $56,000 is the 75th percentile.

Do you have to be smart to be a CNC machinist : Some of the hard and soft skills required to fulfill this role are analytical or critical thinking, technical writing, mathematics, and dexterity skills. Better-than-average additive manufacturing knowledge is a plus. Familiarity with specific computer applications and physical stamina are also among the skills needed.